Products

fdu precast products have many advantages:

- No need for complex formwork on site

- High accuracy

- Quick and easy installation

- Easier surface finishing (can be painted or wallpapered immediately)

- Better planning of construction projects

- Overall cost reduction

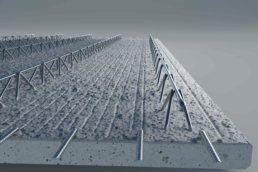

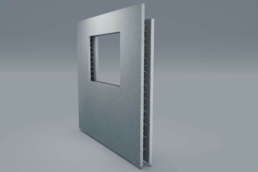

The production process in our factories is largely automated. At the same time, nearly every fdu product is unique – whether it’s a precast ceiling, a precast wall or any other precast part. By using fdu products, customers benefit from both the flexibility of in-situ concrete casting and the simple installation of precasting. The time-consuming part of the construction work is shifted to the factory and can be carried out irrespective of the weather. fdu reduced the total construction time for customers while maintaining exceptional quality.

Our products

Precast concrete parts

We also apply our skills in producing precast ceilings and walls to the production of other custom precast and prefabricated concrete elements. Stairs, balconies, platforms and jamb walls – fdu produces customised solid precast parts and semi-finished parts to meet customer requirements.